For terracotta façade projects, different elevation structures require different construction methods for corner part. There are 3 common methods as follow.

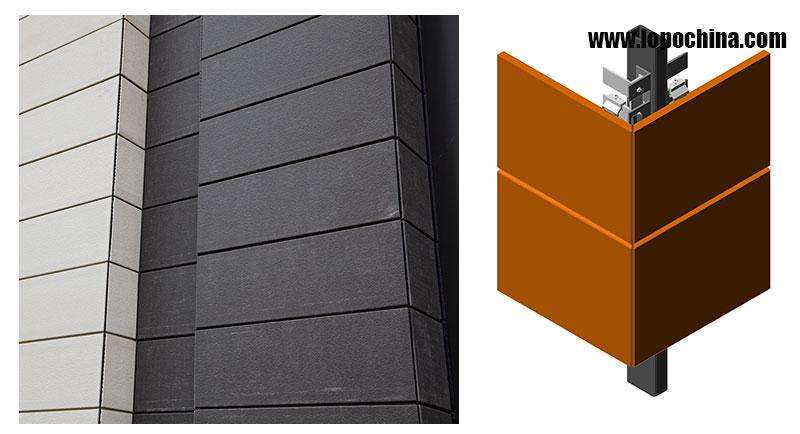

Based on the exterior elevation structure, the edges of each of the two terracotta panels are beveled at different angle to be joined, to form a reasonable and beautiful corner. For conventional façade corners, the most popular construction method is to cut terracotta panels at 45 degree angle. Two beveled terracotta panels are joined to form a 90 degree corner. Afterwards, an EPDM gasket is inserted into the joint, for water diversion purpose. LOPO can provide customized cutting service for every project, to save time and labor cost for terracotta panel installation.

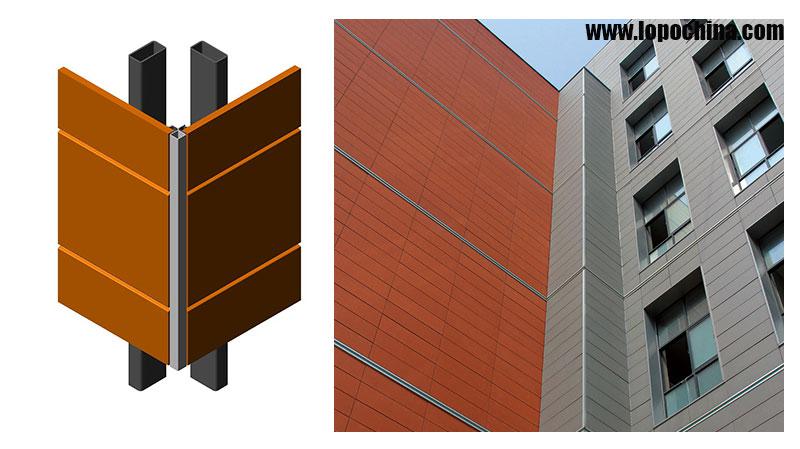

2. Using an aluminum-alloy or stainless-steel flashing

Based on the exterior elevation structure, a flashing is designed for the corner. A flashing is usually made of aluminum alloy or stainless steel, and sprayed with fluorocarbon according to the requirement of the design. For example, a contrast color to terracotta panel could be painted to achieve linear division effect for the façade, or the same color as terracotta panel could be applied to achieve harmony and uniformity.

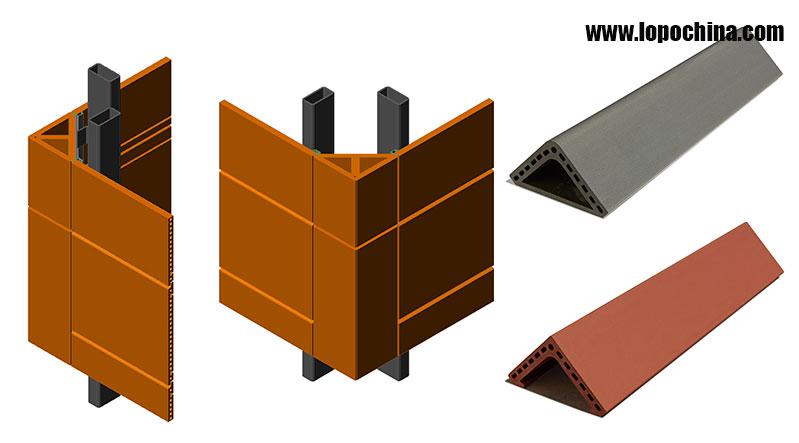

3. Using special-shaped terracotta corner

Many large-scale projects have stricter requirement for the integrity and harmony (such as material, color) of the façade. For this purpose, a supplementary terracotta panel or terracotta baguette is specially needed for the façade corner. A terracotta panel or terracotta baguette with special shape (such as curve, triangle, L-shaped right angle) can exhibit a different façade effect. LOPO can custom design or produce supplementary special-shaped terracotta panels or terracotta baguettes that perfectly suit specific project’s façade corners.

By comparing the above-mentioned three conventional construction methods, we can find that aluminum-alloy or stainless-steel flashings are convenient to process and customized due to the availability of these material used; special-shaped terracotta panels or terracotta louvers can achieve perfect harmony for the façade, but are expensive due to less popularity; miter cutting is most widely used due to its high cost-effectiveness, which resulted from cutting terracotta louver at different degree at the factory before delivery to the construction site for immediate installation.