Premium terracotta facade products require a perfect combination of technology and production facility in each step of the complex terracotta manufacturing process. To improve and innovate our products continuously, LOPO China has been constantly investing in procuring industry-leading, advanced facilities, and customizing and localizing them to better fit our own process features.

LOPO possesses advanced production facilities from Germany and Italy and self-developed kilns, with an annual production capacity of 1500,000 m2 Terracotta Facade Panels, 4,500,000 m2 thin brick, 600,000 m2 Artificial Stone. When it comes to the production energy consumption and environmental protection, all of the parameters have reached industry leading level in China. In 2019, LOPO Terracotta Panels Factory started the construction of the third production facility. This production line will enhance our production capacity for various complex customized products and special terracotta elements.

80,000㎡ Clay Stockpiles

Crusher

150,000 Tons Automatic Batching Systems of Clay Powder Materials

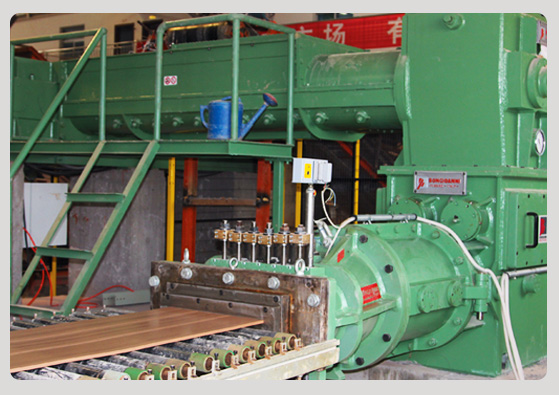

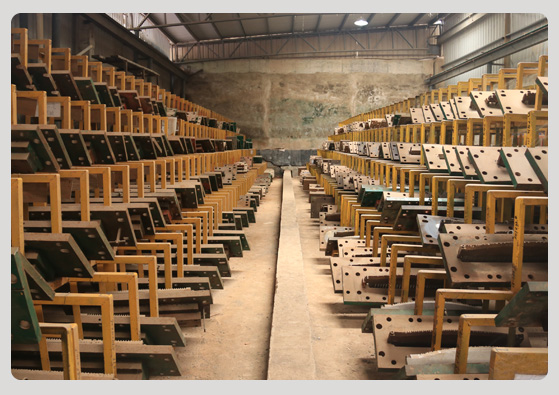

Extrusion Dies for Architectural Terracotta

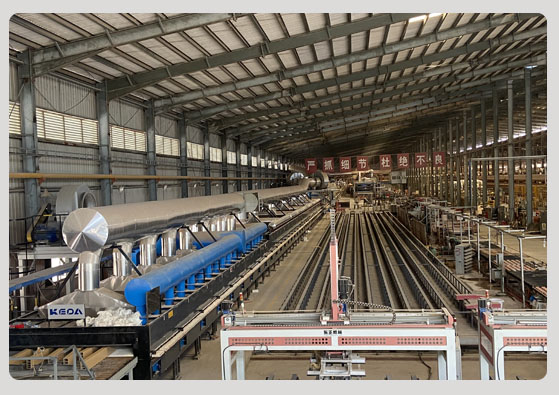

The Third Production Line of LOPO China

Automatic Feeding System for Clay Raw Materials

80 Meters Five Layers Drying Systems

260 Meters Roller Hearth Kilns with Advanced Firing Systems

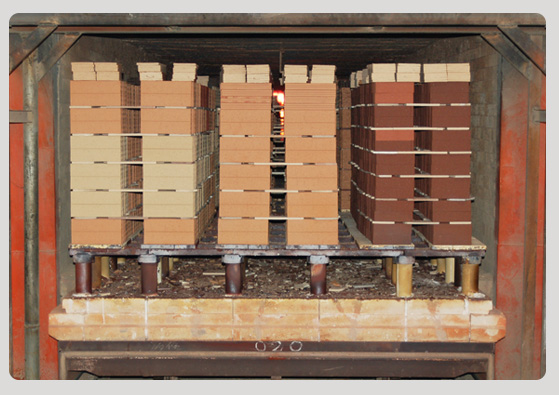

Tunnel Kilns with Programmed Process Measurement & Control

Automated Unloading & Placing System for Terracotta Panels

Automatic Cutting and Edge Grinding Equipments