Photo© CCTN Archiects

By July 2020, the Western China Science and Technology Innovation Harbor will celebrate its one year anniversary of operation. This is one of the ultra-large projects where LOPO China is an architectural terracotta product and service provider. LOPO has produced 110,000 square meters of terracotta exterior wall products for the engineering and scientific research buildings (including 3 megastructure buildings with a floorage of 500,000 square meters), which was Phase 1 of this mega project. Therefore, LOPO selected a dedicated kiln for the production of this project, and ultimately delivered all products within 3 months as required. Furthermore, LOPO has arranged full-time technicians to provide on-site service, so that the project can be completed timely, and efficiently with high quality.

Project Introduction

Owner: Xixian New District Jiaotong University Science and Technology Innovation Harbor Development Co., Ltd.

Architects: Hangzhou CCTN Architectural Design Co., Ltd. (lead)

As a national key project,the Western China Science and Technology Innovation Harbor is jointly initiated by the Ministry of Education and Shaanxi Province, and jointly constructed by Xi'an Jiaotong University and Xixian New District. The original intention of the project was to establish a new form of trinity of 'campus, community and innovation park', thus the university can be better integrated into the society. It is not only an integral part of the society, but also a new form of university for the 21st century, with a global vision and development philosophy. This project marks a new milestone for Xi'an Jiaotong University, which is a century-old school with a 120-year history.

The total floorage of the project is 3.6 million square meters, and it is functionally divided into four major sectors, namely, the scientific research section, the education section, the incubation section and the integrated supporting service section. The research and education section covers an area of around 1.59 million square meters. The project can accommodate about 45,000 people (including faculty members, students and researchers) to work and study here. Therefore, in addition to scientific research and education buildings, this project is also equipped with commercial, and supporting service buildings as well as hospitals.

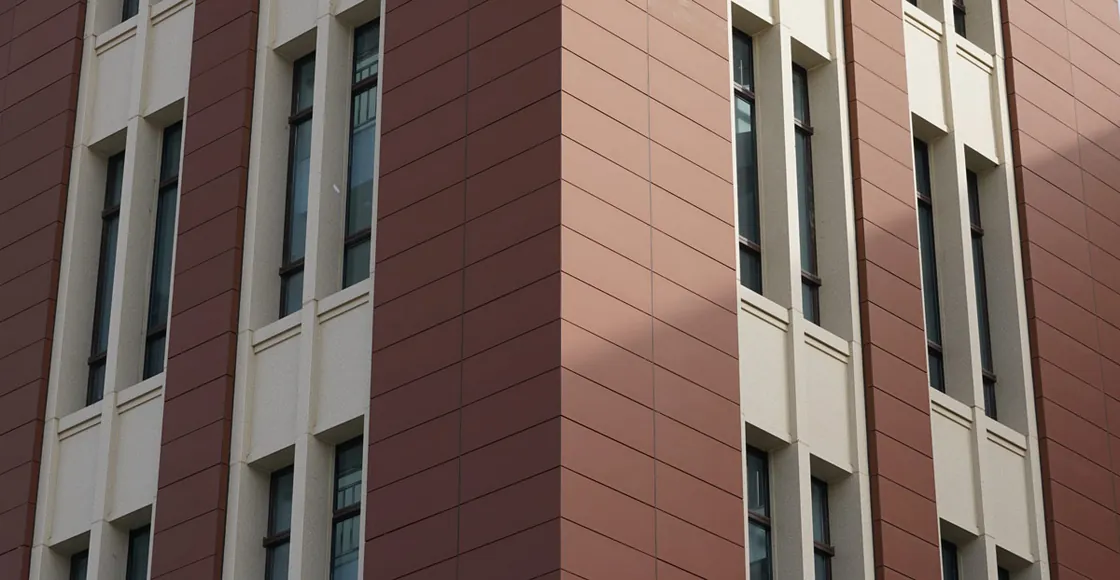

The innovative harbor buildings mainly take the form of multi-story and low-rise buildings (with a story height of 5-6 floors). The buildings feature European modernism style while incorporating the traditional campus culture and design elements of Xi'an Jiaotong University. Most of the traditional buildings of Jiaotong University are red-brick buildings. In order to inherit the architectural style of the century-old Jiaotong University. The building of the new campus adopts terracotta panels with brick red combed surface as their main curtain wall material, supplemented by khaki and ochre-colored aluminum plates and stone materials, rendering a solemn tone and an elegance with classic simplicity.

The designers replaced the original red brick materials of the old campus with a large format terracotta curtain wall of LOPO (with a thickness of 21 mm). Thanks to the use of terracotta facade, it not only enables the architects to achieve their aesthetic and functional needs for the facade design of the project, but also allows the campus buildings to take advantage of the environmentally friendly facade materials, which satisfies the energy conservation and durability needs of the campus building project. As for such a large-scale project, the convenience of the terracotta rainscreen installation system has also improved the construction efficiency, shortened the construction period, and slashed the total cost. From production to installation, it took only 6-7 months for LOPO to complete the facade construction for 3 megastructure buildings projects.

All rights reserved. No part of this article may be reproduced or retransmitted in any form without prior permission of www.lopochina.com